October 10, 2023

Human errors are an inevitable part of any work process involving manual labour, which means they occur in today’s common well design solutions. Most often the consequences are bearable, however, they affect time and cost and can lead to serious challenges.

Modern software solutions contribute to eliminate manual labour such as data input. After working with several well design applications and real-life projects for more than three years, I would like to highlight five sources of human errors, and focus on the immediate mitigation achieved by implementing a modern software that fully integrates the well planning workflow.

Well planning is performed as a combination of manual coordination and handling of data inputs followed by an iteration of software calculations and simulations before producing a finalised drilling program.

Many different stakeholders and disciplines are involved in the workflow and different parties are responsible for different elements of the planning processes. These processes take place over a long period of time and many iterations are often required before a drilling permit is provided by the governing bodies.

Obsolete software solutions combined with increased focus on time and cost reductions contribute to a work environment where manual errors can occur, and they are not always corrected before it is too late, if at all. These errors reduce the quality of the planning process and could have a negative impact on operations.

Let us take a closer look at five common manual errors in well planning and the associated areas of improvement that can boost compliance, safety, and performance.

1. Errors that occur when entering data

We have all experienced having ten thumbs from time to time, and typos are difficult to avoid. Most of the time, these are easy to detect, but for various reasons, some of them will linger without correction.

Human error is inevitable and we typically accept their existence albeit unwillingly. What we can do, however, is reduce the number of these errors by eliminating the cases in which they occur. An important aspect of streamlining work processes is about reducing the number of recurring events, and automated data treatment and input facilitates undisturbed action patterns.

Seamless import and exports, integrations for data transfer, and automatically triggered data updates reduce the manual human involvement, including the source of errors and potential ripple effects.

Automatic processes can of course involve consequential errors if the input was initially incorrect, but the efficiency gains by eliminating manual handling are freeing up time for more careful inspection and follow-up of the results. A single source of data enables automated quality assurance processes.

2. Manual file management and shuffled versions

The calculation chain of the well planning workflow has (until now) occurred as separate work processes with the use of various tools and software solutions to perform necessary calculations and simulations. A wide array of calculations and simulations utilizing the same associated input data live in isolated systems.

If changes occur in one part of the calculation chain, these changes must be manually implemented in other systems to be recalculated and before proceeding to the next step.

Additionally, you will often be left with a varying number of different versions in each of the systems that must be kept track of, and the importance of using and matching the latest version becomes a manual and error-prone task. These challenges can be avoided by using a software solution which incorporates an integrated workflow. Most of the tasks and activities in the well planning process are influenced by each other and should be interconnected.

3. Manual rounding of input parameters

Different practices in manual rounding and truncation can have significant effects on simulation results. Especially if the combination of several significant round-offs occur in one and the same data-set.

There is an inherent savings potential when increasing the precision in well design. If one manages to remove the sources of significant errors before the drilling program is implemented, this can result in increased efficiency, safety, and utilization rates of the wells.

Often, the solution to the problem lies in the company's own standards and practices. The risk of rounding errors increase significantly when involving an increasing number of data sources, practices and parties.

In Oliasoft WellDesign, different fields of expertise can work in the same application with the same single source of data, eliminating transfers and individual data treatment. It is possible to invite internal and external parties to contribute to datasets and designs, and at the same time avoid them operating in their own bubble - this immediately removes silos and improves communication between the people involved.

4. Lack of consistent update of changed parameters throughout the design

At the beginning of the well planning process, complete information is seldom provided and new information will trigger updates and changes along the way. This can involve reversal of previous work if the change has a significant impact on the design. These updates can be costly and time-consuming, especially if they occur frequently throughout the well planning workflow.

When significant changes occur, the engineer's expertise comes in handy, and a skilled engineer will immediately know the effects of the change, and what needs to be adjusted to account for the new information. The problem is that this is a repetative manual task that needs to be done, often several times, which is not resource-efficient.

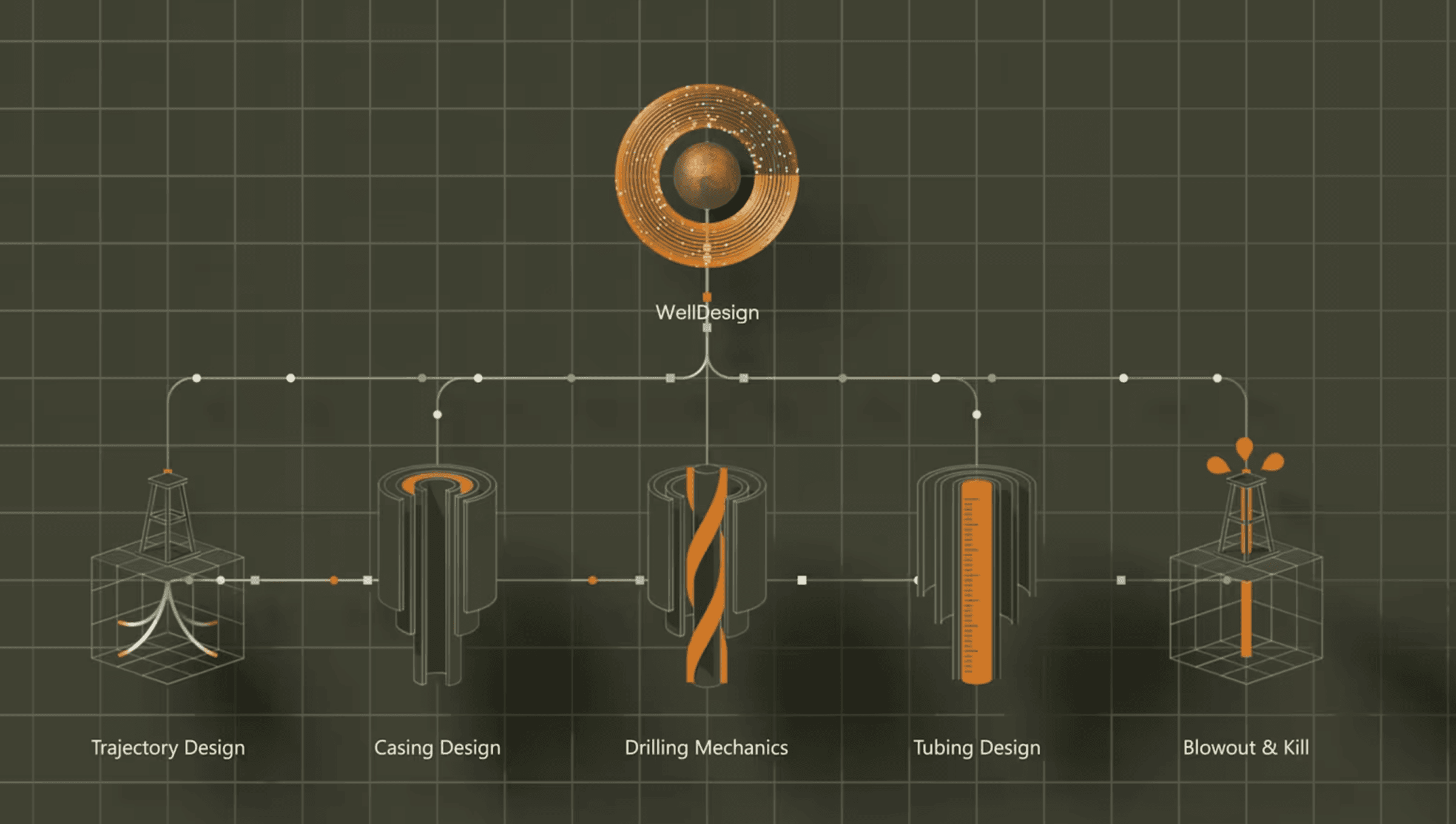

Oliasoft WellDesign covers all required calculations for well design and planning with an integrated workflow and includes the calculation chain for trajectory design, casing design, drilling mechanics, and tubing design, as well as state of the art blowout & kill simulations. If you need to make an update or adjust data input in one of the fields, recalculation of the entire design is triggered, and you will always have an updated design that reflects your latest work, without having to retrace your steps to ensure you have an updated version. An integrated workflow provides a complete 360-degree view and continuous updates of all parameters affecting the design, hence, reducing the occurrence of manual errors.

The greatest advantage of having an integrated calculation chain with the same data source is the ability to do iterations and sensitivity analysis and immediately see how this affects your design. This frees up time to experiment with different solutions and to find the optimal design for any project.

5. Manual shortcuts to account for unknown and unexplored areas

Well design is a profession of high-quality assurance and precision and we do not have access to perfect information at all times, and assumptions must be made and shortcuts created to get the job done.

With several open and accessible systems, with various purposes for solving tasks in order to improve the quality of drilling wells in the oil and gas industry, it is easier to find new and better ways to carry out mutual use cases that solve common problems and bring domains closer together.

Ecosystems of cloud solutions that can be integrated using APIs (application programming interface) lower the threshold for exploring and implementing synergies across domains and disciplines. This will gather and improve insights, information, and decision-making.

A digitised and open software structure does not provide us perfect information, but it will immediately provide a less fragmented picture and better methods of accomplishing things.

So, what is this really about?

In recent years, technology has made more user-friendly software and computing power available, which has led us to be increasingly surrounded by good examples of how much easier and better ways we can perform various tasks. Examples from our private lives are innumerable, but working life has also been revamped lately, with office and meeting policies dictated by the ongoing COVID pandemic. Modern society highlights the benefits and gains of making things digital, easier, and more accessible.

A software solution adapted to both the purpose and the user can provide great value, both in time saved and by mitigating the unconscious and uncontrolled sources of error. In order to succeed in minimising the sources of errors, it is required that you perform a thorough structuring job in order to get the right framework and routines in place, both in data quality and data transmission.

With modern technology, this is a job that only needs to be done once. With the structure in place, there are great opportunities for upscaling, and one can move away from data handling and manual entries i.e. the sources of errors.

When we talk about using digital tools that are open, integrated and more intuitive, it does not mean that the machine does a better job than the engineer - but that the tool elevates the engineers enabling them to spend more time on skill-demanding tasks and to dig deeper into their cases and produce outcomes and decisions of a higher quality.

Oliasoft WellDesign is a well planning tool created by engineers for engineers, and will empower its users to do a better job, resulting in improved well designs, time and cost savings, and safer, more efficient drilling operations.