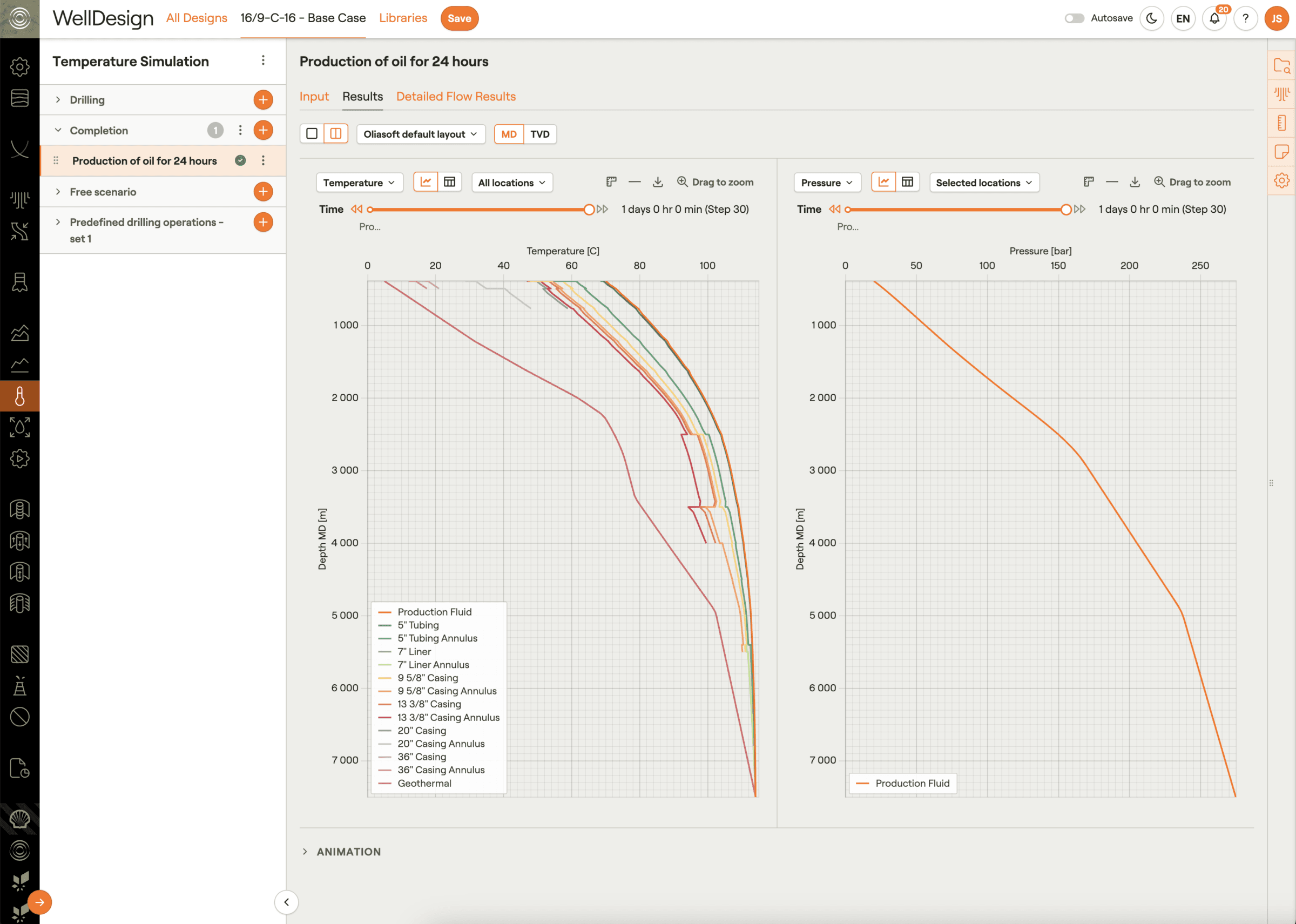

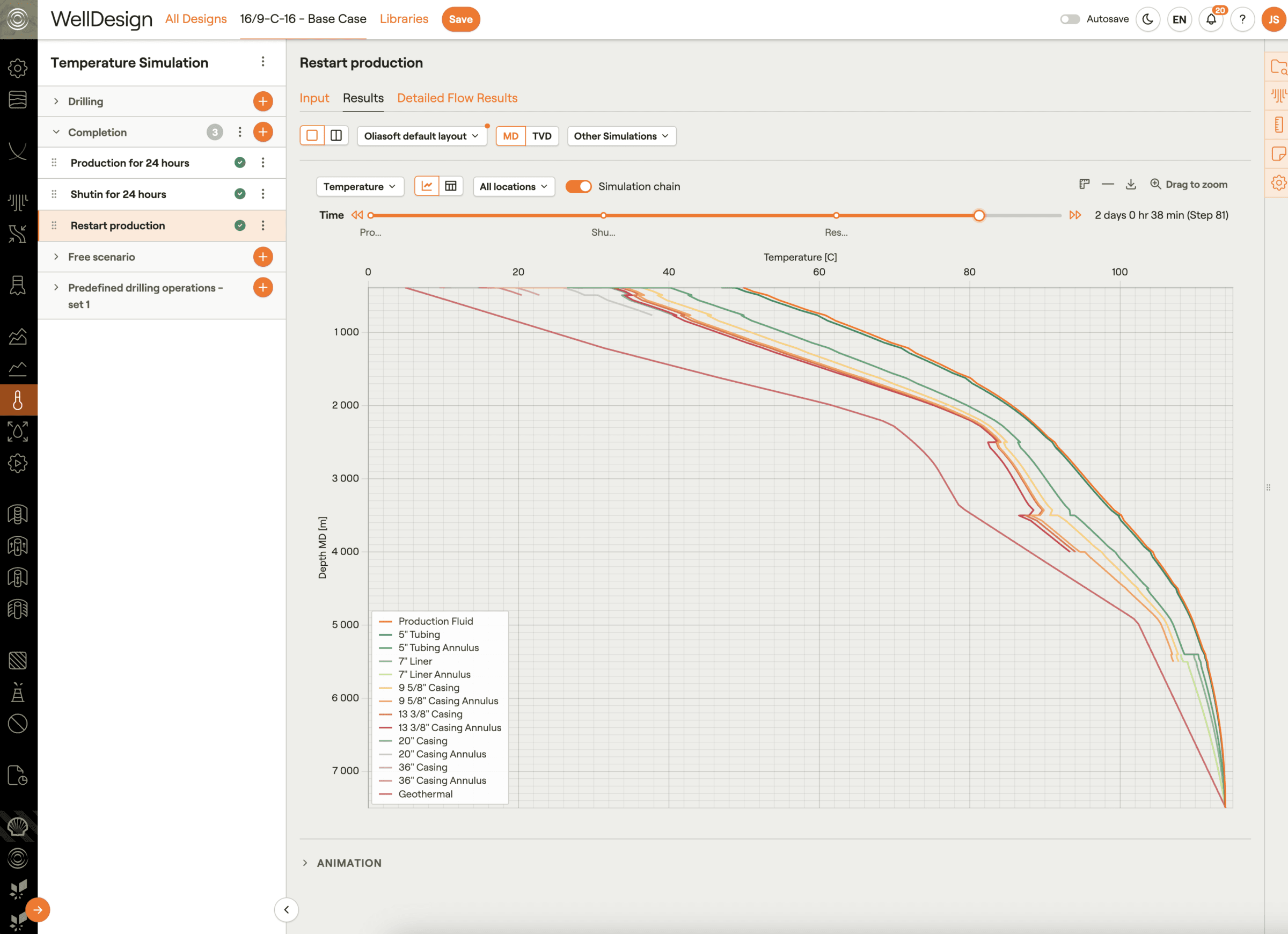

Oliasoft Tubing Design’s transient simulator handles all operations from multiphase fluid production through to tubing and annulus injection, and circulation to shut-in scenarios.

Our advanced finite volume thermal simulator calculates temperature and pressure development for all annuli - including cement and formations - in any well configuration.

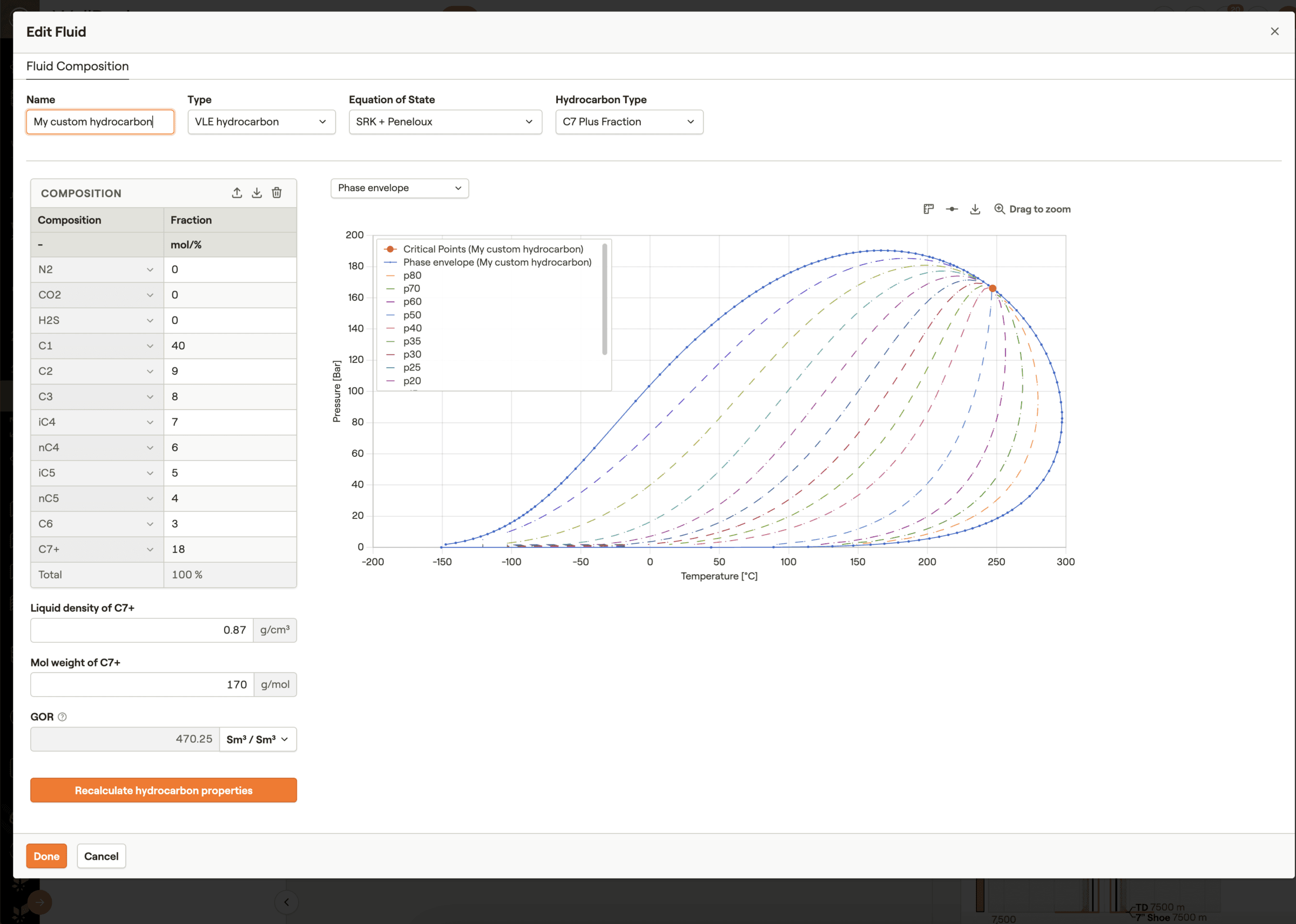

Users can simulate hydrocarbon flow in wells utilizing advanced Equations of State (EOS) such as SRK and Peng-Robinson, with or without Peneloux correction. These EOS models accurately predict properties like density, compressibility, enthalpy, and entropy across various pressures and temperatures. The system supports C7+ and “no plus” fluid characterizations and comprehensive “black oil” correlations to enable users to define their fluid in the way they prefer.

Perform unlimited nested operations to ensure accurate simulations and thermal profile development. Produce transient thermal profiles for use as appropriate across the Oliasoft WellDesign workflow.

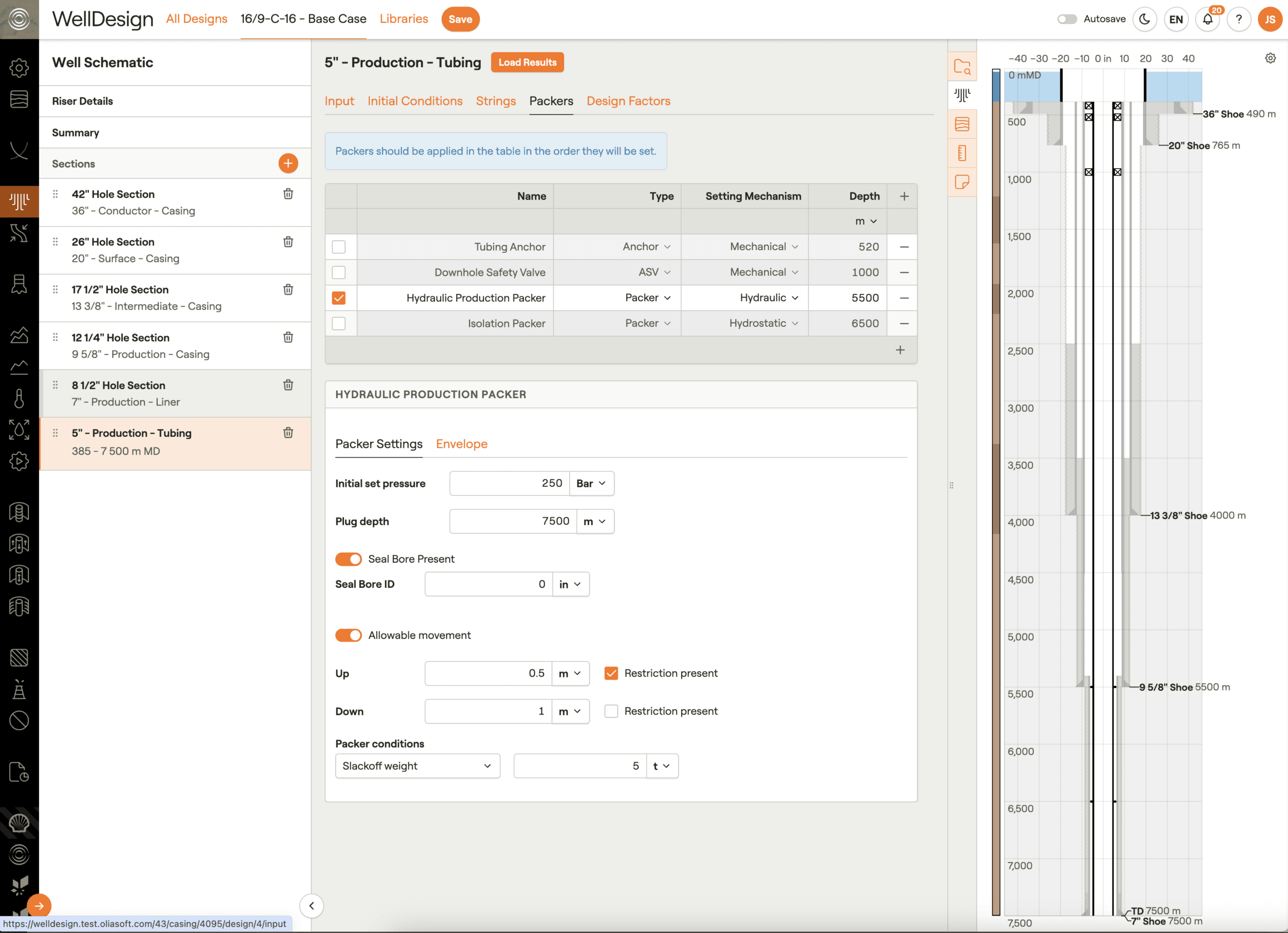

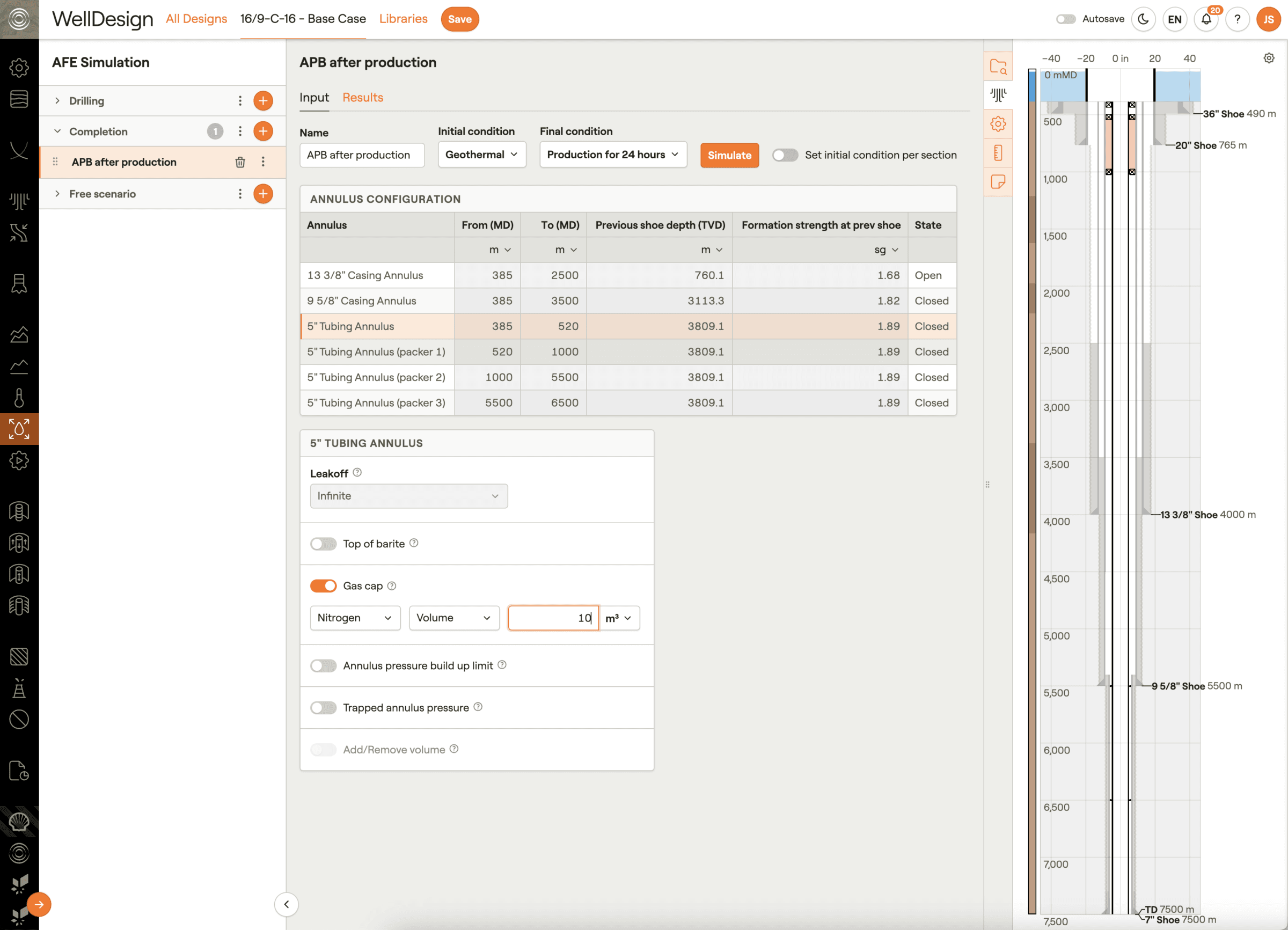

Define tubing string design through tailored packer configurations, with temperature simulations linked to casing and tubing load selections.

Simulate annular fluid expansion supporting multiple mitigation effects and other multi-string effects, ensuring designs meet both NORSOK-D010 and BSEE requirements. Our thermal simulator is continually refined in partnership with Norway’s Institute for Energy Technology (IFE).

Key features