January 13, 2026

Casing and tubing design sit at the core of well integrity. Every decision must balance safety, performance, and cost, often under tight timelines and increasing well complexity. Yet in many engineering workflows, these critical designs are still built through fragmented tools, manual input, and repetitive setup.

Oliasoft WellDesign changes that by bringing casing and tubing design into a single, integrated, and automated engineering environment. With rule-based workflows, real-time visualization, and seamless data flow across modules, engineers can focus less on setup and more on engineering judgment.

Casing design is one of the most complex and risk-sensitive stages of well planning. Engineers must account for a wide range of load cases, pressure scenarios, and operational conditions, often rebuilding similar setups across wells and projects.

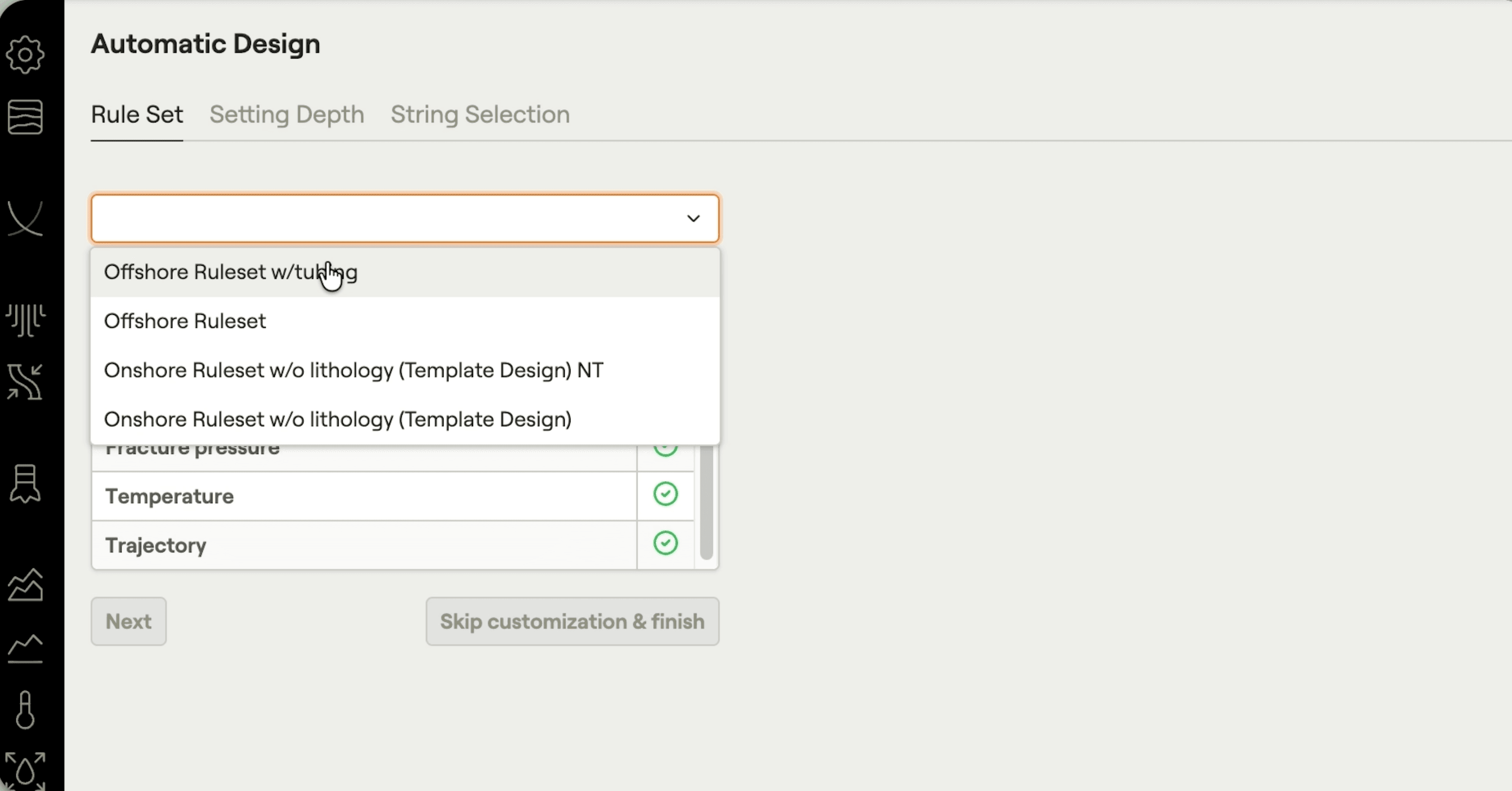

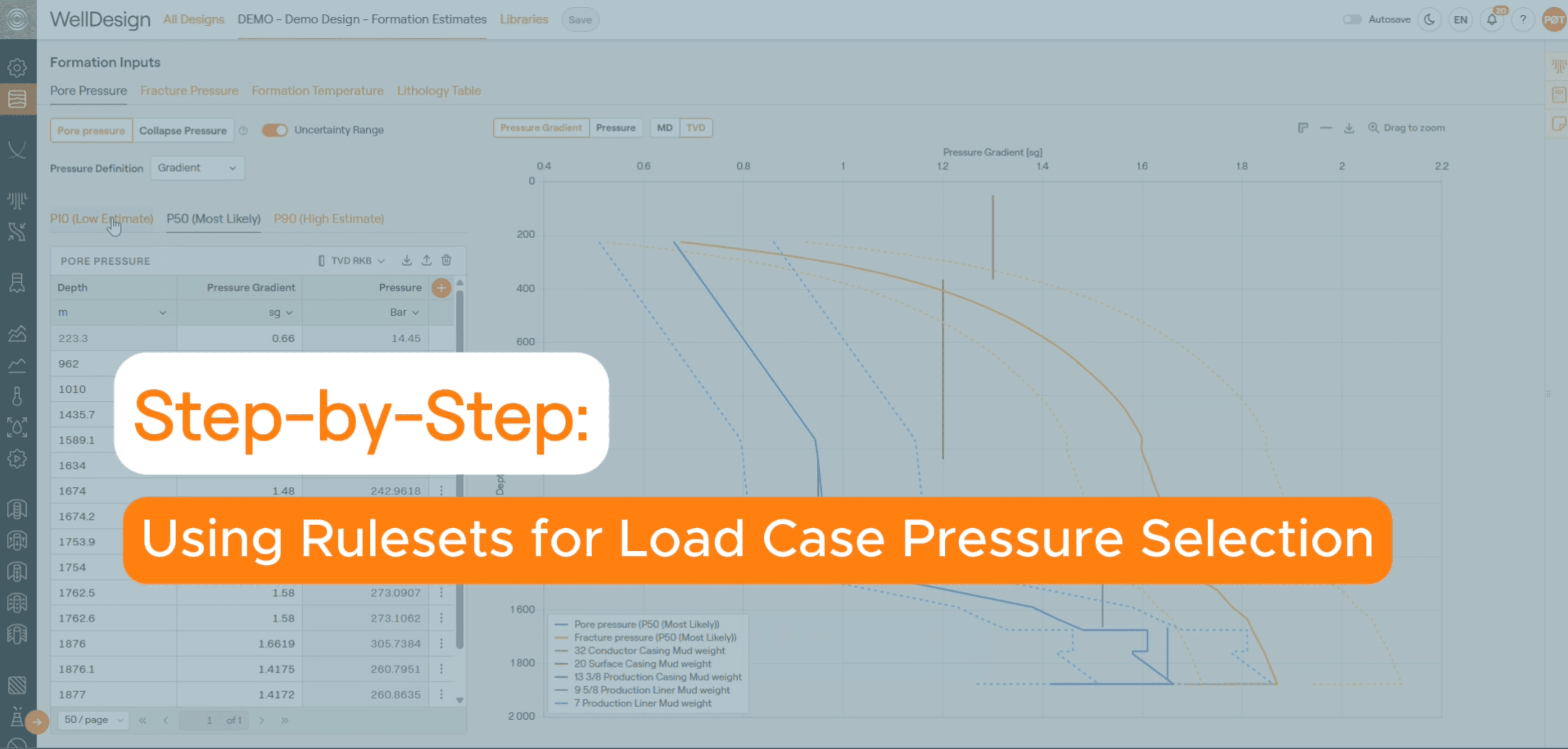

In Oliasoft WellDesign, casing design is driven by rulesets. Instead of manually defining load cases for each design, engineers can create standardized rules once and reuse them across wells. Subject matter experts can define, review, and lock these rulesets, ensuring clear ownership of assumptions and consistent application across projects and teams.

This approach reduces setup time significantly while improving quality and traceability. Engineers spend less time preparing input and more time analyzing results, validating assumptions, and optimizing designs.

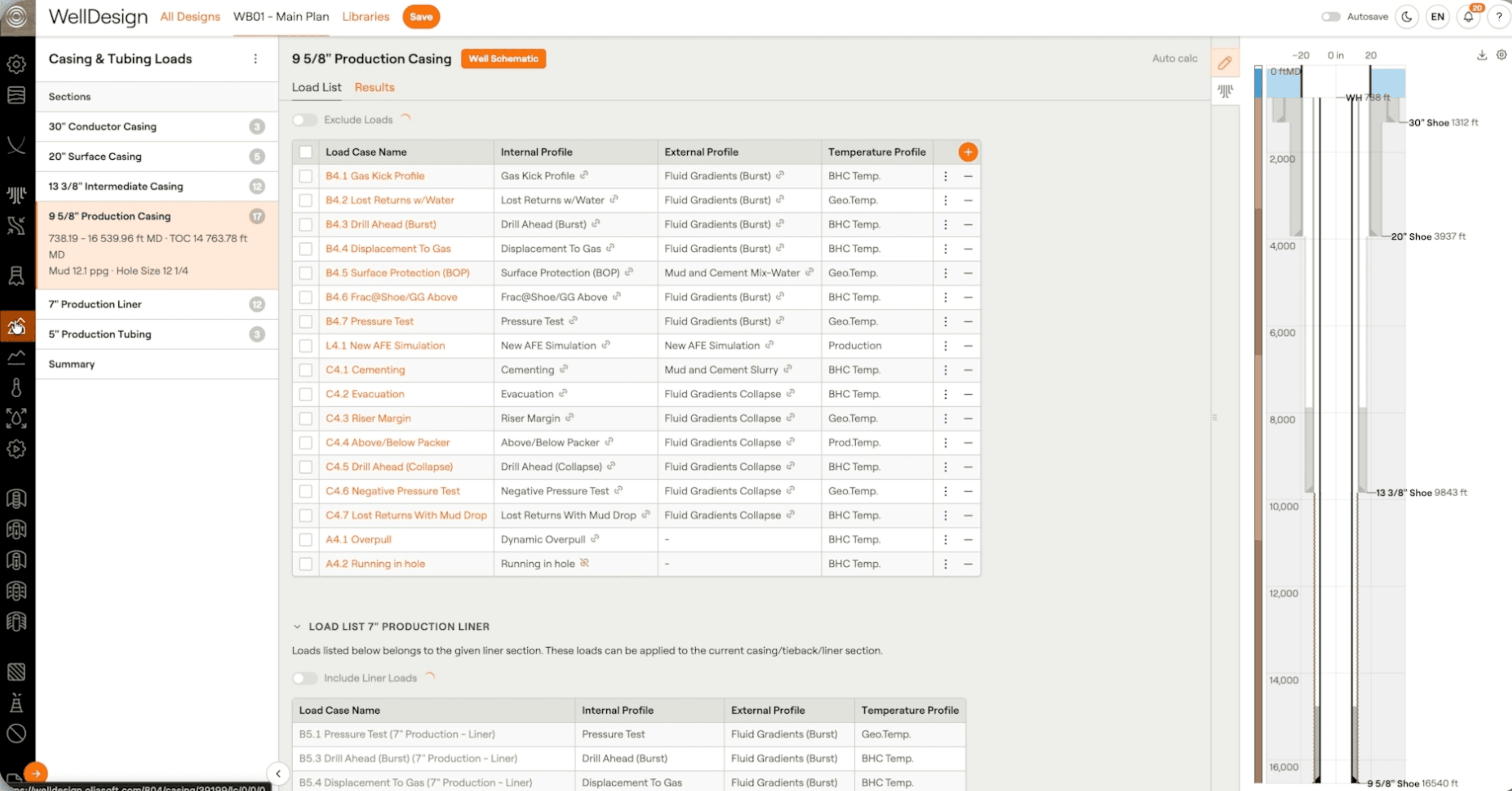

Oliasoft WellDesign includes an extensive library of predefined load cases commonly used by operators worldwide. These cover typical operational and failure scenarios, including loads from subsequent liner sections, allowing engineers to assess casing performance throughout the well lifecycle.

When project-specific conditions require something different, engineers are not constrained by defaults. Custom loads can be created easily using the flexible load module, with pressure and temperature profiles imported from existing cases, spreadsheets, or entered directly. This combination of structure and flexibility allows teams to meet internal standards without sacrificing adaptability.

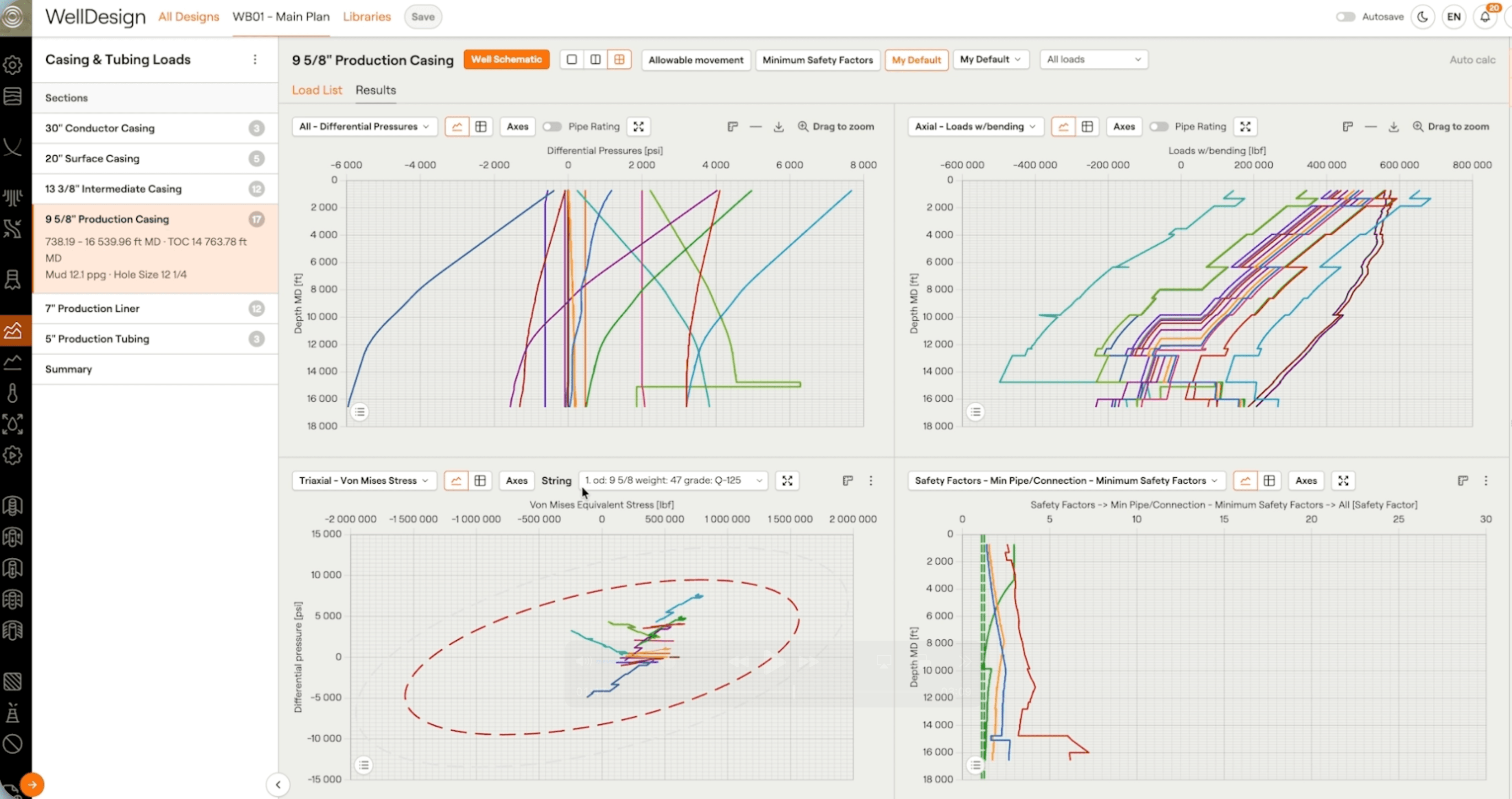

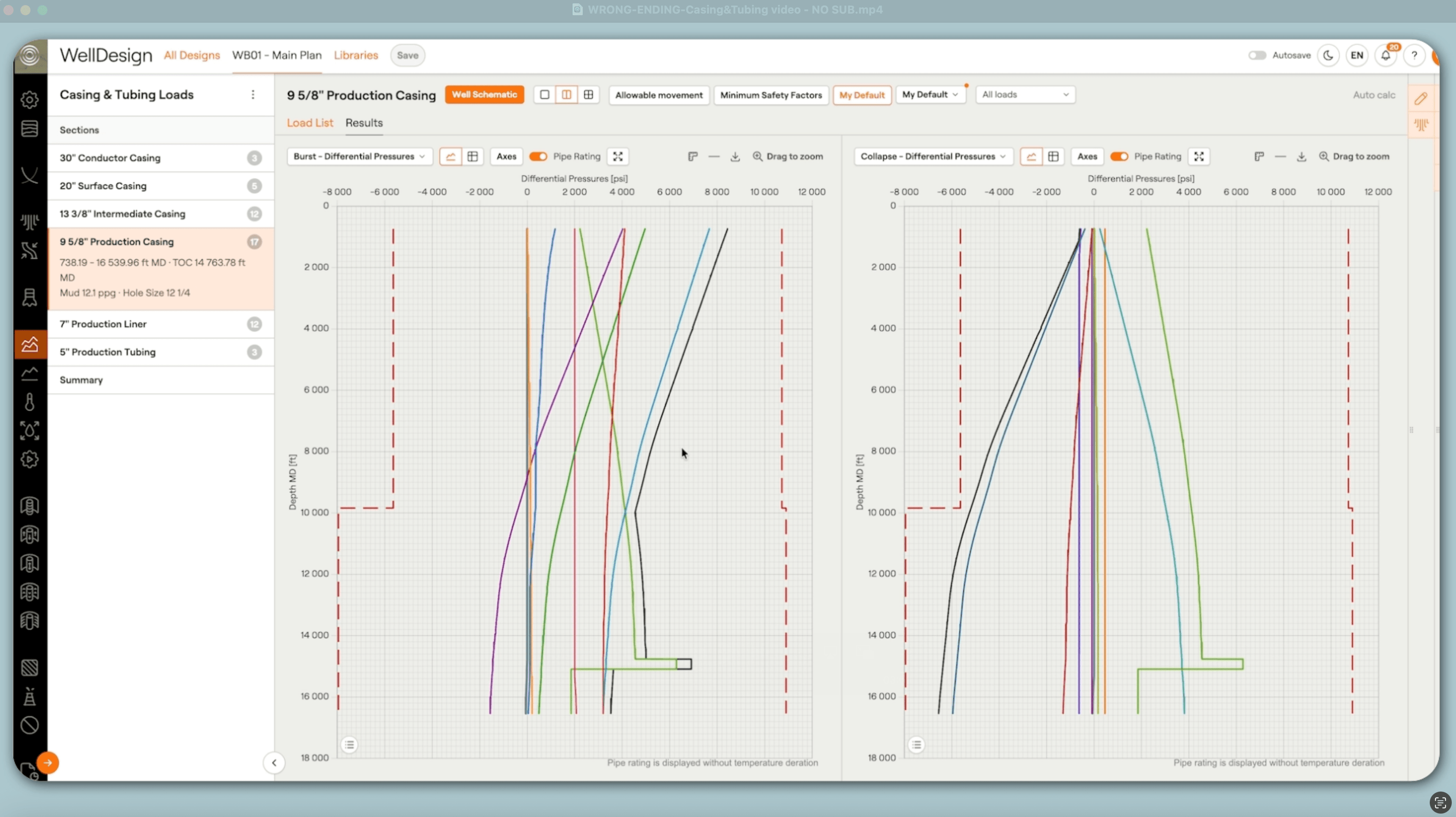

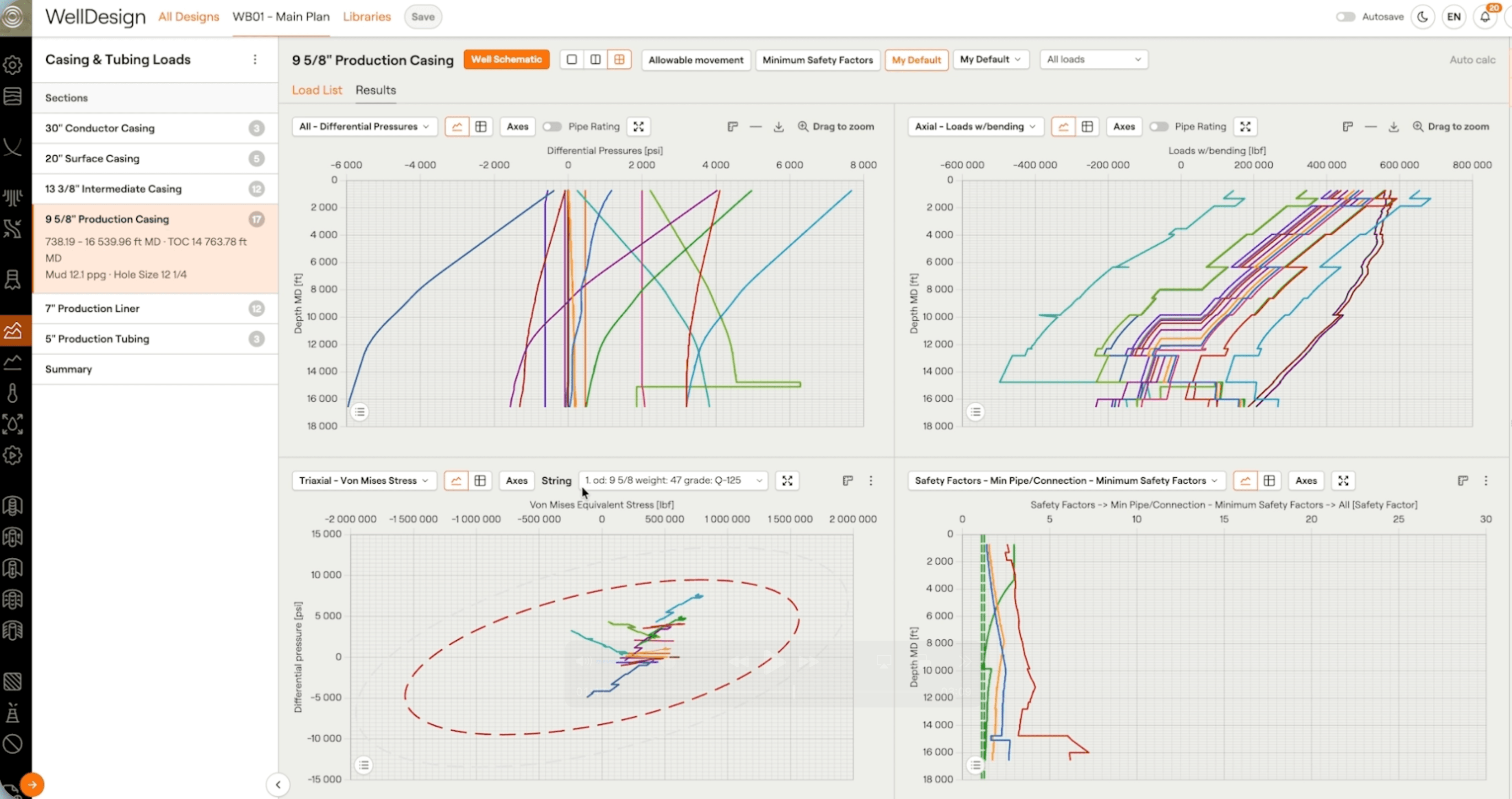

One of the defining strengths of Oliasoft WellDesign is real-time interaction. Engineers can add, edit, or combine load cases and immediately see how changes affect results. Stress envelopes, burst, collapse, and tension plots update instantly, enabling rapid iteration and comparison of scenarios.

Multiple result charts can be viewed simultaneously and saved as personalized templates, making verification faster and more consistent. Transparent rule logic and live visualization help engineers clearly understand tradeoffs between safety margins, material selection, and cost.

Once casing design is validated, tubing design continues directly from the same well model. There is no re-entry of data, no file transfer, and no loss of context.

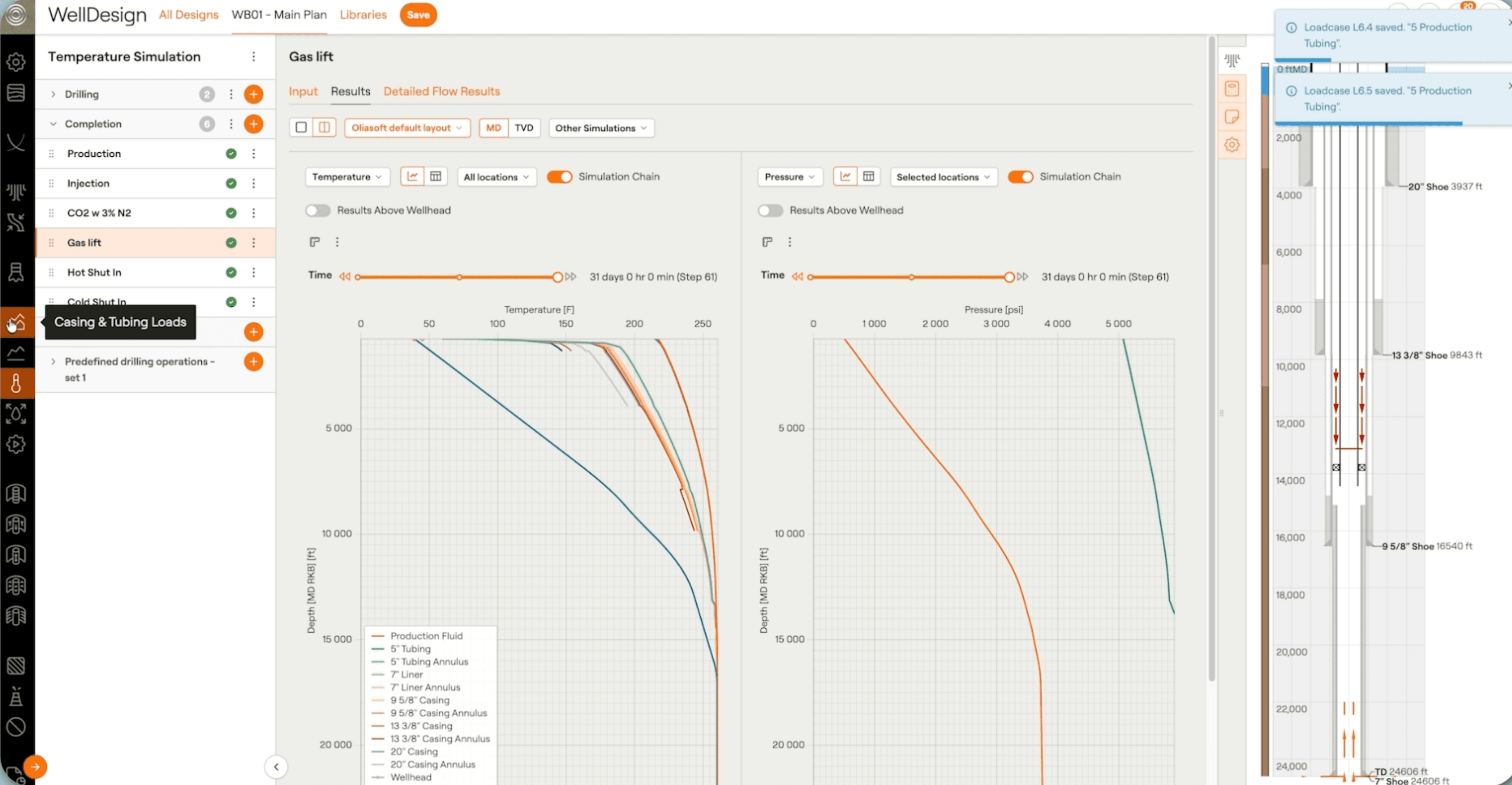

Oliasoft WellDesign includes a comprehensive temperature simulator and production modeling capabilities to support tubing design across production, injection, and shut-in scenarios. Engineers can model fluid behavior, pressure and temperature effects, and combine production simulations with annular pressure build-up analysis to ensure the tubing design accounts for all lifecycle conditions.

Rule-based workflows are also available for tubing design, allowing companies to standardize production scenarios and design criteria. This ensures consistency across assets while freeing engineers to focus on quality assurance and optimization rather than repetitive setup.

What ties casing and tubing design together in Oliasoft WellDesign is integration. Inputs and results flow automatically between trajectory, casing, tubing, and drilling mechanics modules. Engineers no longer need to move data between disconnected tools or manually synchronize models.

Open APIs and cloud-native architecture extend this connectivity beyond WellDesign itself, allowing integration with planning, operations, and enterprise systems. The result is a single source of truth for well design, built for collaboration, scalability, and engineering accuracy.

Integrated Casing and Tubing Design From Simulation to Execution

While automated casing and tubing design covers a broad range of capabilities, this short demo zooms in on one specific aspect — using rulesets to control pressure selection at the load-case level. It shows how targeted automation can reduce manual steps while supporting conservative design decisions.

February 23, 2026

February 18, 2026

January 13, 2026